Mill Stands

ASPM manufactures Mill stands which have rigid structure and thus are reliable. We Manufacture mill stands which have quick roll change capabilities and are have fully automatic operations to produce bars, wire rod, angles, channels, and universal beams.

The conventional mill stands consists of housing and cap assembly wherein the rolls rotate in bearings-fiber/anti friction bearings, house in chocks which move up and down in housings with liners. The roll gap is adjusted through screw down mechanism operated through worm & worm gearboxes mounted on the top of the housing cap. The rolls are powered and driven by electric motors through system of drives and spindles.

In each stand the housing and cap assemblies are connected through fabricated members both on the top and bottom side which hold them together and work as one single entity, taking all rolling loads through chocks, screw down system. Our mill stands are engineered based on balanced housing design that give minimum deflection under rolling loads.

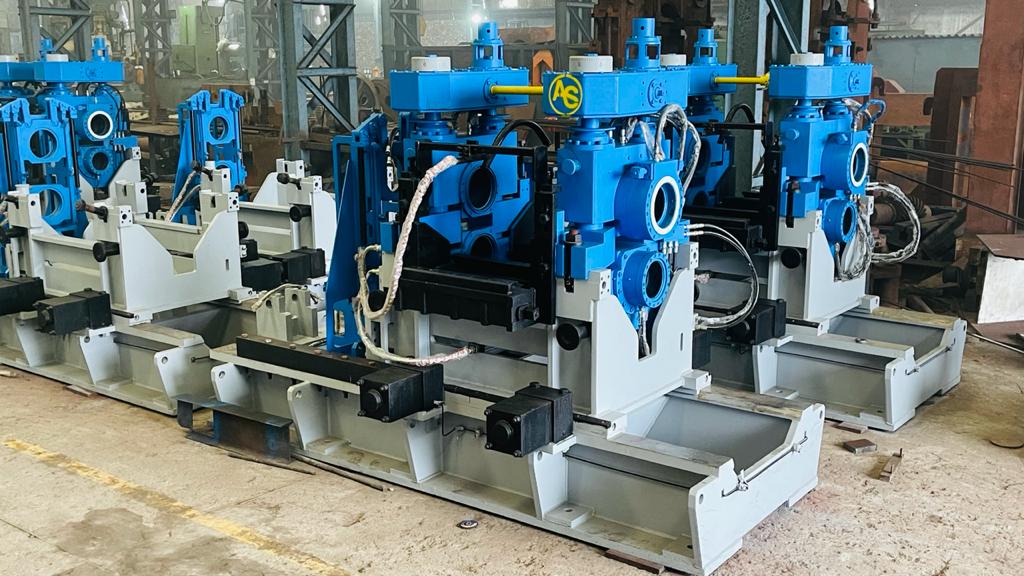

Housingless Stand

These housing less stands, as the name suggest do not have housings and caps, but the chocks carrying the roll assemblies are connected through four (4) housing screws mounted with worm wheels and worm which move either manually or through motor for roll gap adjustment.

The unique feature of the housingless mill stand is that the entire rolling load is shared by all the four pressure screws. The bearing life is enhanced as the rolling load is carried over a larger arc of contact in the chocks. These housingless stands consist of short stress path and hence the mill module is high and helps in reducing the product size deviations over the stock length as also small deviations in temperature of stock do not adversely affect the product tolerances. We offer a combination of horizontal & vertical housingless stands in order to give sequential pass reduction without twisting the material and hence little chances of mill cobble (misroll) is ensured. The mill stands are provided with axial movement feature by which a fixed pass line is achieved by shifting to new roll grooves in line with other continuous stands which are also on the same pass line.

4Hi Stand

The mill as the name suggests consists of two back up rolls and two work rolls housed in the same housing. These are very much in vogue for the flat and strip mills. The work rolls bite the material and the rolling load is transferred to the larger back up rolls with high capacity bearings. The work rolls being small in diameter have small area of compression and hence the rolling load is less. However here the bite angle limitations have to be seen otherwise the material may start slipping and may not enter the roll bite.

Pre-Stress Stand

The mill consists of Conventional mill stands but the mill is pre-stressed with the help of hydraulic four nuts that pre-stresses the system such that the mill is preloaded to the maximum roll separating force during rolling time. When the stock passes under the rolls there is practically no further deflection of the mill stand under rolling load.

Convertible Stand

Cantilever Stand

The cantilever stands are basically designed like a block mill and can be configured horizontal or vertical as per design requirement. The rolls are mounted on sleeve bearings so that high mill speeds can be achieved to produced wire rod 5.5mm to 8mm.

The cantilever stands are basically designed like a block mill and can be configured horizontal or vertical as per design requirement. The rolls are mounted on sleeve bearings so that high mill speeds can be achieved to produced wire rod 5.5mm to 8mm.

Here the rolls are relatively small discs with width available for one or two passes, mounted on the cantilever shafts. The roll material is very hard and often made of tungsten carbide.